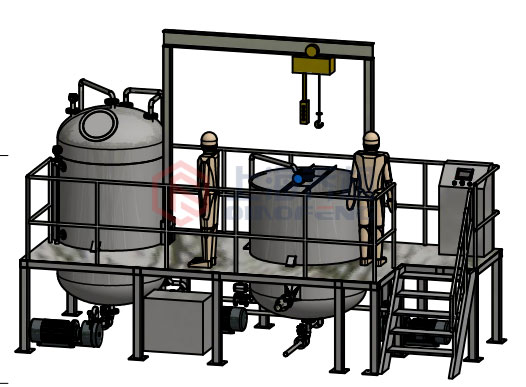

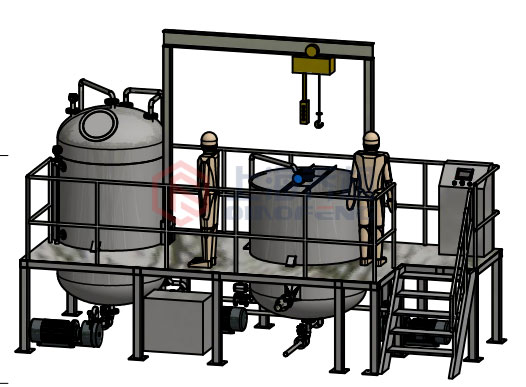

Mixing tank (stainless steel 316L material is used for all parts in contact with materials)

1. The mixing tank has a diameter of 1.6 meters, a volume of 2.4 m3, internal polishing and external wire drawing, and the contact parts with materials are made of 316L stainless steel.

2. The top cover of the tank body is designed as a detachable two-part type, which is convenient for cleaning the inside of the tank in the later stage. The Alfa Laval cleaning ball and feed inlet are installed on one side of the cover plate, and the metal hose connection is used at the interface to facilitate the removal of the top cover in the later stage.

3. The mixing motor adopts horizontal deceleration, and the mixing paddle is designed to slide on the mixing rod to adjust the mixing position, and the mixing rod adopts the interpenetrating design to adjust the mixing position.

4. The center of the tank body is equipped with a flange type sintered plate filter with filtering accuracy of 5um, and the available size of the filter is φ 1300mm. The filter is designed as a detachable cleaning structure. In the later stage of cleaning, only the fixing screws need to be removed, and the electric movable elevator at the top of the tank body is used to assist in cleaning the filter inside the tank body.

5. The solid discharge port at the side of the tank body is designed as the outlet with the width of 200 and the height of 100. The outer part is changed into a round pipe with a diameter of 89 for discharging, and the sanitary quick loading ball valve is installed.

One side of the tank is equipped with a three-way ball valve which is connected to the bottom of the tank for cleaning and discharging.

Storage tank (stainless steel 316L material is used for contact parts with materials)

1. The diameter of the storage tank is 1.5m, and the volume is 3.4m3. The tank is polished internally and wiredrawn externally. The tank body is made of 316L stainless steel with elliptical head structure.

2. The tank top is equipped with Alfa Laval cleaning ball and cleaning manhole, which can clean the tank interior.

3. The tank body is equipped with magnetic flap liquid level transmitter and pressure transmitter, which can be fed back to Siemens PLC fast control system through signal feedback, observe and set the condition value to alarm.

4. The discharge port at the bottom of the tank body is equipped with a φ 51 pneumatic quick loading ball valve. The outlet of the ball valve is connected to the sanitary centrifugal discharge pump, and the liquid pumping volume of the discharge pump is 10t / h.

Feeding part (stainless steel 316L material is used for all parts in contact with materials)

1. The feeding pump adopts sanitary centrifugal pump, and the pumping volume is 10t / h.

2. The connection part of the pipeline is designed with quick opening structure.

Vacuum pumping unit (stainless steel 316L material is used for the contact parts with materials)

The vacuum unit adopts a vacuum pump with a rate of 165m/ h. The negative pressure reached 0.096 PA. The pump body is made of stainless steel 304.

2. The vacuum pipeline is equipped with one-way valve to prevent the material from being pumped into the pump body in case of misoperation.

3. The water ring vacuum pump is equipped with 300L circulating water tank, and the water tank is equipped with automatic water replenishing valve and sewage valve.

Solution tank:

1. The cleaning ball adopts Alfa Laval cleaning ball without dead angle,

2. The pump adopts vertical stamping pump with small flow and high pressure, and the water consumption is 2T / h

Electric belt:

1. Siemens control system is used for electrical software control part, and Schneider Electric is used for strong current control part.

In addition, the safety and convenience of installation of PLC control system are related.

Through bioinformatics analysis, molecular modification and other technical means, Hanhai new enzyme successfully screened a protease K mutant with high tolerance to organic solvents. By using Shanghai Qiaofeng spray freezing and vacuum stirring equipment, the production process of protease K was optimized, the production efficiency was increased by 3 times, and the production of protease K was realized in kg level, making it the largest protease K production in China We believe that the timely supply of protease K can produce more nucleic acid detection kits, and provide more help for friends at home and abroad. Let's fight together to win the new crown pneumonia and return to normal life as soon as possible!